Finding your suitable jb weld marine grade is not easy. You may need consider between hundred or thousand products from many store. In this article, we make a short list of the best jb weld marine grade including detail information and customer reviews. Let’s find out which is your favorite one.

Best jb weld marine grade

Rank

Product Name

Score

Related posts:

Best jb weld marine grade reviews

1. Hy-Poxy H-450 Alumbond 6.5 oz Aluminum Putty Repair Kit

Feature

Epoxy metal weld for aluminumRepairs HVAC, radiators, engine blocks, boat hulls, equipment, appliances

Can be drilled, tapped, sanded, threaded and painted

Gives you a non rusting, non magnetic aluminum gray color, stays gray even after sanding/polishing

Made in the USA

2. J-B Weld 8272 MarineWeld Marine Epoxy - 2 oz.

Feature

J-B WELD MARINEWELD: A two-part epoxy cold weld system that provides strong, lasting repairs to multiple surfaces. Perfect for all DIY marine and watercraft repairs.CURE AND SET TIME: After mixing the tubes at a 1:1 ratio, it takes 4-6 hours to set and 16-24 hours to cure. Once cured J-B Weld MarineWeld can be tapped, filled, sanded, molded and drilled. J-B Weld MarineWelds set and cure color is dark grey.

VERSATILE AND DEPENDABLE: J-B Weld MarineWeld is steel reinforced, has a tensile strength of 5020 PSI and can withstand temperatures up to 550 degrees Fahrenheit (287 degrees Celsius). When fully cured, MarineWeld is waterproof and resistant to petroleum, chemical and acid. It retains strength above & below water.

SURFACE APPLICATIONS: Aluminum, Fiberglass, Metal, Plastic/Composite, Wood.

DO IT YOURSELF: Big or small, you can DIY it with J-B Weld. Our heavy duty epoxy and adhesives repair & restore it right the first time. J-B Weld delivers superior performance, quality, and results for the Worlds Strongest Bond.

3. MASTERCOOL 90934 Alum Bond A/C Repair Epoxy - 2 oz.

Feature

Hardness (Shore, ASTM D 1706): 83DCoefficient of Thermal Expansion: 40 x 10-6 cm/cm/ DegreeC

Compression Strength (ASTM D 695): 8600 PSI (59 M Pa)

Tensile Strength (ASTM D 638): 3500 PSI (24 M Pa)

Maximum Line Pressure (after 5 hours application time): 650 PSI

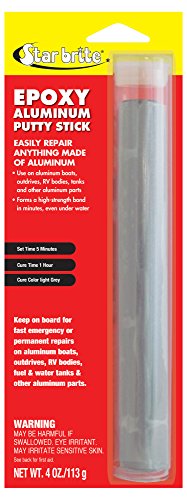

4. Star Brite 087004 Epoxy Aluminum Putty Stick, 4 Ounce (Pack of 1)

Feature

Works underwater! Every boater should have this onboard for emergency and permanant repairsEasy to use - hand knead for 1 minute and apply to damaged area

Bonds in 5-10 minutes - Steel hard in 30 minutes Fully cured in 60 minutes and can then be sanded, drilled and tapped

Special additives cut through oxidation and anodization to maximize bonding to weathered aluminum

Withstands high temperatures and pressures making it ideal for manifolds, mufflers, & drive units

5. J-B Weld 8272 MarineWeld Marine Epoxy - 2 oz, 2 Sets

Feature

25 ML. epoxy syringe specifically formulated for the marine industry6. PC-Products PC-11 Epoxy Adhesive Paste, Two-Part Marine Grade, 1lb in Two Cans, Off White 160114

Feature

Two-part marine epoxy adhesive paste bonds materials in dry, wet, and underwater environmentsBonds many materials, including fiberglass, concrete, many metals, glass, ceramic, and rubber

Can be used in indoor and outdoor applications, with a temperature range of 35 to 115 degrees F and a service temperature range -20 to +200 degrees F

High-tack paste can be used in vertical and overhead applications

Resists mild acids, caustics, detergents, gasoline, fuel oil, and fresh and salt water

7. J-B Weld 50172 25 ml. MarineWeld Syringe

Feature

Flash point: 93.0 degrees_celsius8. West System 650-K Aluminum Boat Repair Kit

Feature

Each kit contains 8 ounces of G/flex 650 Toughened Epoxy, adhesive filler, application syringes, mixing pots and reusable mixing sticks and protective gloves.Used to repair leaking seams and rivets in aluminum boats and canoes.

Working time: 75 minutes @ 72F

All components are contained in a sturdy, resealable package.

9. 50172 MarineWeld Marine Adhesive Epoxy Syringe - Dries White - 25ml, Pack of 3

10. J-B Weld 8272 MarineWeld Marine Epoxy (3)

Feature

Two-part epoxy cold weld system specially formulated for marine applicationsGreat for bonding aluminum, metal, composites, fiberglass and more

Sets in 4-6 hours at room temperature and cures dark grey in 15-24 hours

Once cured, it can be shaped, tapped, filed, sanded and drilled and will retain its strength above or under water

J-B Weld is proudly made in the USA